The rapid change of the world makes innovation a lethal weapon to become a big part of solution to bring about countries, companies, or communities to a useful change that hopefully take them to the top the leading pack in the world. Little research on the topic could give many hints that innovation is the key. There are now disruptive innovation, cultural innovation, reverse innovation and other terms that use innovations as the key.

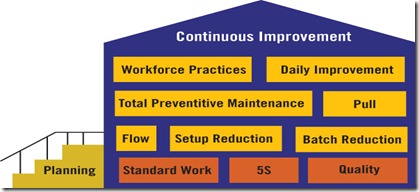

However, the overwhelming topic of innovation that filled the market has overshadowed some important not so radical, slow and not extreme change that comes from continuous improvement that actually be the backbone of many leading companies in the world. The power of kaizen culture which embedded in top leader of the pack has been uncover in the book The high-velocity edge by Steven Spear seems to be undermined by the amount of innovation books and its varieties on the market.

I am not against innovation because I understand that without innovation no companies could ever bare their existence let alone leading. innovation is the key. I really enjoy reading books on innovation especially books by Clayton M. Christensen which really is the result of his in-depth research and reflection about the world of innovation.

My argument about innovation is that most of the books on innovations discussed about big changes that will lead to strategic/big step. My take on current innovation paradigm is that innovation is not enough because we still need kaizen. Some people say that kaizen is innovation also, but it really is not. The rule of thumbs is what your mind perceived what innovation is, reduce it by factor of at least 100.

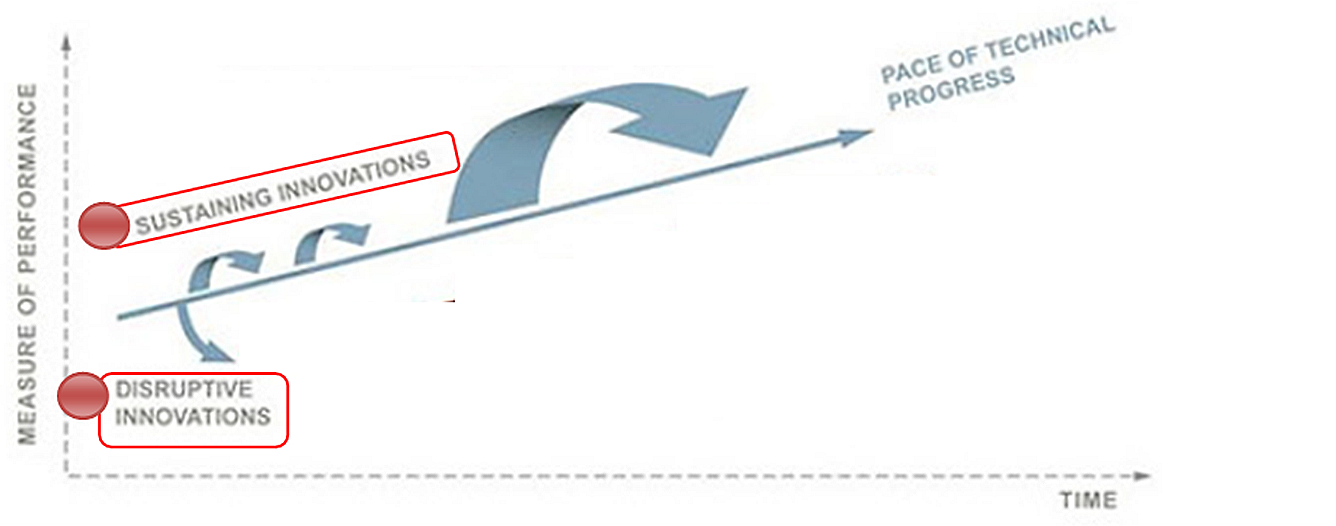

When for example Clayton M. Christensen tried to detail innovation into a more elaborate by dividing it further into Disruptive and Sustaining Innovation. People get confuse because first, where is then Kaizen? Second, a strange combination of words is used (Sustaining Innovation!).

The Innovator’s Dilemma (Christensen 1997) identified two distinct categories—sustaining and disruptive—based on the circumstances of innovation.

- Sustaining Innovation : when the race entails making better products that can be sold for more money to attractive customers—we found that incumbents almost always prevail.

- Disruptive Innovation :when the challenge is to commercialize a simpler, more convenient product that sells for less money and appeals to a new or unattractive customer set—the entrants are likely to beat the incumbents. This is the phenomenon that so frequently defeats successful companies. It implies, of course, that the best way for upstarts to attack established competitors is to disrupt them. (Low end disruption and New market disruption)

Confusion happen among the practitioner of whether Sustaining Innovation is Kaizen because it is also about making better products to attractive customers. Additionally, two words of sustaining and innovation are both contradictory in nature in a way that when innovation happen, change happen and it moves the object of innovation to some future state.Thus actually it is inappropriate to give the name “sustain”. Sustain means almost equally to maintain. Hence it means the innovation going nowhere but only maintain and hence going nowhere.

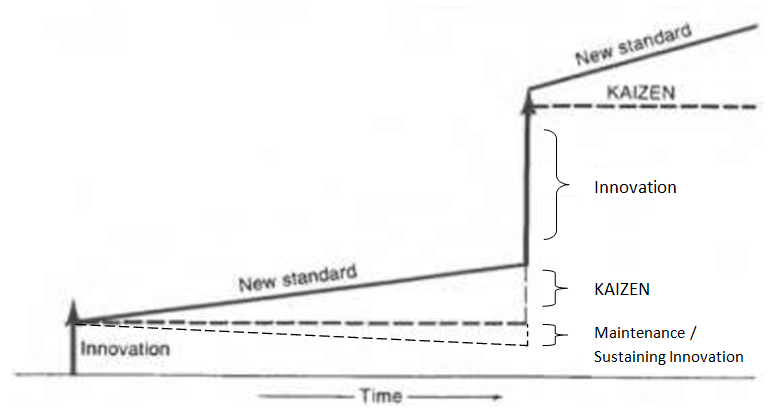

History wise, the Kaizen term exist already since 1986 which is kaizen/continuous improvement which small incremental improvement. However, it seems that the founder of kaizen concept had predicted that confusion between Innovation and Kaizen will likely to happen.

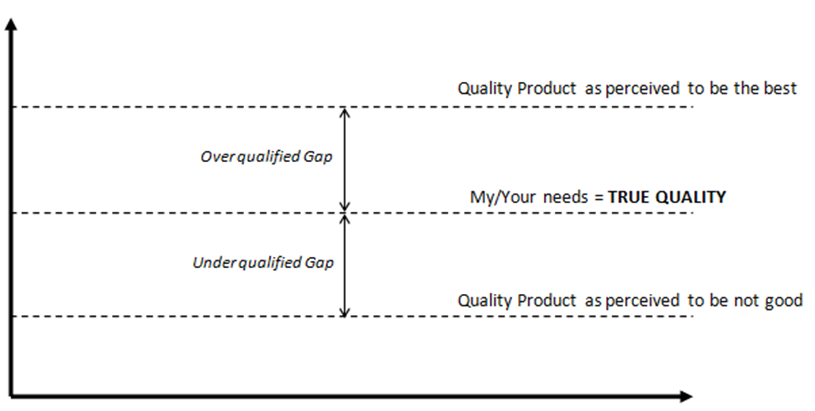

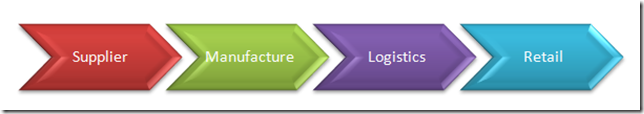

This big misconception has been cleared before by Masaaki Imai in 1986, a notable quality philosopher and practitioner and the founder of Japanese consulting company namely Kaizen Institute or best known by the west as the father of Continuous Improvement. Misconception of innovation happen when people associate immediately innovation with improvement. The truth is that innovation indeed is improvement but improvement is not just innovation. Improvement consist of Kaizen and Innovation in which until the next innovation, kaizen will improve the system little by little.

From the graph it is clear that Kaizen perfected Innovation. It means that any types of Innovation whether it is disruptive innovation, cultural innovation, reverse innovation will be make perfect by following through with Kaizen afterwards. Kaizen will target improvement until next innovation.

Hence it is very clear that innovation itself is insufficient to create a winning edge and that innovation coupled with relentless kaizen become the ultimate answer. This is why in my opinion, despite of the effort to rally with other companies toward Innovation from generating, managing, until applying innovation many firms still happen to be in the lower league. Because Innovation without Kaizen is just like “Pound Saving, Penny Foolish”. It seems good that you get to save many Pounds, but other companies take care also every Pennies possible with Kaizen and overtime they who cares for both thrives.

Related articles

- #TheRichestMan-n-Babylon: “Kaizen Philosophy” (josiahlawhorn.wordpress.com)

- Phil Kuhlenbeck – Kaizen Blog (kuhlenbeck.wordpress.com)

- How to be innovative? Get out of your office! (hiscox.co.uk)

- Disruptive Innovation. Hmmm. (historysfuture.wordpress.com)

- What is Karakuri Kaizen? (michelbaudin.com)