Having read the A lean journey blog that gave a quote of the week about “Can We do Better?” “YES”, I get so inspired yet give rise to unresolved questions that coming up to my mind after I read the article.

Maybe, it is better that the unanswered question be described using a small true story that I experienced.

I have a maid, whose job is to come everyday to my house leaving her husband and two kids to clean my house. She will clean every room in my house from living room, bed room, kitchen, until toilet. I have just getting mad at her because she supposed to also clean my bedroom but it appeared that she just passed my bedroom and not doing the mopping, sweeping, and tidying that she is responsible for.

I thought maybe she just have a rough day to get over so I just neglect it. But the next day, the same thing happened again and I confront and ask her for a confirmation. unexpectedly, she is the one who is getting irritated with me because she felt that I accused her for not doing her job while she actually did clean my room. While calming myself from her reaction, I followed up with a probing questions and found out that she in fact thought that the cleaning job that she had done was fabulous according to her.

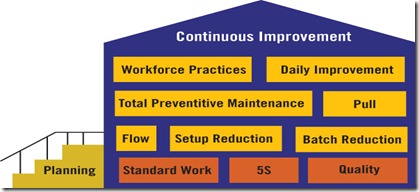

That night, I went into reflection and thinking deeply about how that could happened. I learn and passionately searching about Lean that basically doing things better or Kaizen about continuous improvement, but in my own backyard, in my house, I got a person working in my house who is my maid that basically have a different standards compare to me about the definition of “a clean room”. For her, since she lives in a village, she define “a clean room”.is that room that I call dirty because I live in a city. Thus, we have a different standards about “a clean room”.

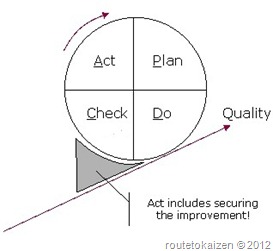

The rising questions is how she could do better at cleaning my room while according her standards she has already done a wonderful job. How to make her realize that what she did actually is below my standards and that she could do better willingly and improve her performance and quality.

This is somehow related with quality perceived by customers. In my country, quality is not the main concern because people is still buying products even not a high quality. They bought it because their standards is rather low, so that when the products that being produced in my country want to be exported, then the gap about standards become a barrier for my country’s products to sell. On the other side, people on my country has no pressure or willingness to do better in production because they still think that it sells well. The labor is not trying to improve the process because without improving it, it still sells even just for local market. Their standards become inertia for their self to reach the next level of doing better and to continuously improvement.

The question is “How?”. How to make them realize that the standards that they are living in is not fitted anymore and needed to be improve and in fact could be improve if they realize that they need a new standard.