Jokowi is a name that is probably unknown for people that lives outside Indonesia. It not uncommon that his name was not being heard, because even in Jakarta, the capital city of Indonesia, his name could only be heard for first time in the late of 2012 where people started to get awareness of him. Currently, he is a newly elected Indonesia’s Governor which for many people sparks a new light of hope in Jakarta City.

I am not interested to discuss about government or the best ways to manage a city. Instead, we will use him as an example of how a high velocity organization could arise not only in manufacturing, service industry, or military, but also in public administration system. Yes, yes, I know that Jokowi has just been elected as a Governor of Jakarta around fourth quarter of year 2012. But we will later see, as I elaborate later, why I think that his management system will end successfully.

Watching people managing any systems is the same as watching a football match, you knew already who will win the match before the match over by watching both teams play. But you will still wait ‘till the end of the game to make sure that there is no coincidence that the other team unexpectedly win. Good managed team will win 90 % of the time while the rest of 10% is attributable to special variation.

In football game, those persons that often watch football match will know that a particular team will win against another before the game is ended. The way strategy is being executed in the football field will shows how the players play together, using each persons’ skills and combining strength to reach synergy that collectively create a good play. A good team come from a good manager. A good manager might not be the best player in the field. He could be the best player, but for sure he is at best at managing system. A good system will triumph most of the time, with some special minor exception of good system that failed to succeed.

Companies in any industries has a role of managing its system. The unique things is that they all have different products as well as customers. Hospital, Manufacturing, Tourism, Public Administration. Thus, there are different ways to deal with managing system in each of these industries. However, managing a system is always have the same principal across industries, with some modifications to the industry we are trying to apply it in. Here, I will present some facts across industries that mainly drawn out from my main industry of expertise which is automobile and try to show you how Jokowi acts matches with what has been a successful and proven philosophy in the world of automobile.

1. To change a system, you cannot be inside it.

Jokowi know this very well. He is not trying to change the system by being inside it, but he directly go “on top of it”. Unless we have one person that can changed the system on the top of organization’s pyramid, we cannot changed it by entering into it. We have to be above it. There is no use if you have an idea that could significantly changed the system when you are down below pyramid in a bad system. It is because in a bad system, your good idea considered as bad. because bad system nurtured bad ideas. Thus, only bad ideas goes into the top of the pyramid and got heard.

Jokowi is not trying to be hired as an employee, but he aimed for the top. He knew that if he want to changed the system, it has to be from the top. Many times good and diligent people got into a bad system and in no time these people tired of challenging bad inertia in the bad culture that has already ingrained and these good and diligent people become adapted to a bad system by producing bad ideas and doing unproductive activities.

Many cases that geniuses that have great academic records, or good carrier in foreign country, when they tried to come back to build their own country, they are shocked that they found their brilliant ideas are not working. People do not agree, not supporting it, or maybe no one believes it.

Mr. Habibie is so great at anything about airplane. He foretold “I want to make an airplane for my country”. He is more than a genius. But again, in a bad system, he just not fit. He successfully created PT.Dirgantara, but it wasn’t successful because that time he has to interact with a bad system that exist in the country. Bad system is like a disease, it spreads to others around it so quick.

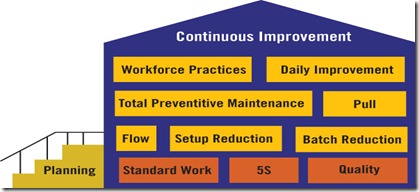

2. Create a system perspective for everyone

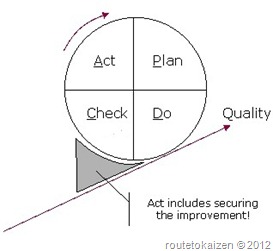

Everyone could work hard and do their best but still at the end the result is failed. As Dr.Deming said, it is no use to do your work as best as possible. We have to do the right things before we do our best. To make people able to evaluate themselves that they have already do the right things, people has to understand their position within a system and hence they know how to contribute to it.

In Toyota and in high velocity organization such as Pratt & Whitney’s, Southwest, Alcoa, and other leader in their own industries, knowledge of how a particular section or job fit into a whole system is very important to know for all the people inside the system. Toyota have always explained and educated a new employee about his role and responsibility. But in addition to that, Toyota makes sure that this new employee also know about how his role and responsibility will impact the whole system by explaining the whole system from manufacturing, quality , engineering ,design and so on.

Taking complex system, then divided it into parts, try to manage each part as best as possible is absolutely false. Because it tries to improve each part taken separately and destroyed the system. It is like taking a big mirror from store and you break the mirror into parts for optimization in carrying it to your house and when you reach your house, you reassemble the mirror again, and you are then shock that the mirror looks different, it do not work when you want to look at yourself and the parts seems not fit together as it was in the store. Because It simply have broken.

Jokowi tries to fit everyone to the whole picture by not only making everyone realizes their role and responsibility within a system of public administration, but also that he shows to all employees about the whole system. For example, he put out a YouTube channel that could be seen by all employees so that employees know what really governor do and what really happening in other sections of public administration so that they can really contribute by doing the right things at their best.

3. Going to “Gemba” and “Genchi Genbutsu”

Gemba is a Japanese term that means real place while Genchi Genbutsu means to look by yourself the particular physical things that being a concern. People in automobile always use this concept of management extensively. Managing from office is not enough because paper based management neglect real concerns. By the time the problem is translated into paper and travel to office as a report, many things has already been happened and information may also lost in the way or got distorted by the time it reached office. Additionally, information, if not getting distorted it will somehow go perish and by the time people from the office try to reconstruct the problem, all people connected to it has forgot about it or the environment has already simply changed. It is because Information has a characteristic of sensitive to distortion and perishable.

Thus, going to Gemba will means getting problem found from the right persons in timely manner, isolate as quickly as possible before spreading, and solve as soon as it arise. Going to Gemba also means Genchi genbutsu or seeing the real thing as it is.

Jokowi really knows the values of going to Gemba and Genchi Genbutsu. He first of all realizes that civilian in Jakarta is his customers and the success of his organization is the satisfaction of customers. Therefore, getting the customers’ concern is a top priority. He knows very well that customers is where he could really get the real problem on time without distortion and therefore despite of all the accusation that he is wasting time, he still do go to Gemba.

In addition, Jokowi’s success in Solo city where he lead for several years as Governor before he became governor of Jakarta is not merely because of he is a superpower person or a very genius person. He might be one of them, but alone, only destructive change that could result ( firing, hiring, penalty, force procedures). Instead, he manages the system with constructive change that can only be achieved through collaboration and cooperation that obviously not a work of a single hero. Thus, those leader that could really turn the situation is good at managing collaboration and cooperation as a vehicle to constructive change. Instead of using power to generate policy that is destructive to system. These leaders can use it to create collaboration that will be fruitful as these leaders believe that change should come from collaboration that arise from a system management. This will make a lasting change even after the leader is not anymore responsible for the system because the system has already built, run, and improve itself.

Leader’s Job is to lead not merely giving orders.